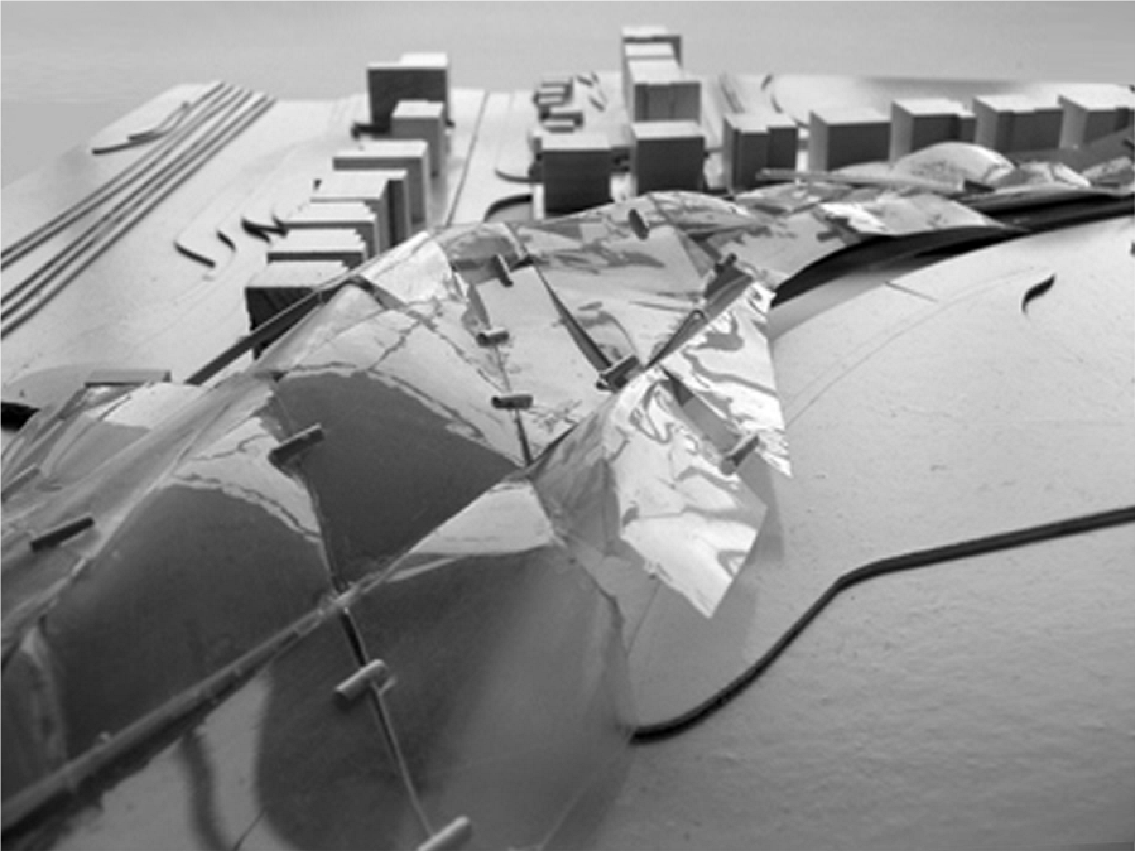

The principal materials used in the construction of the model are sheet acetate, white plastic coated wire, and sheet mountboard over an MDF base.

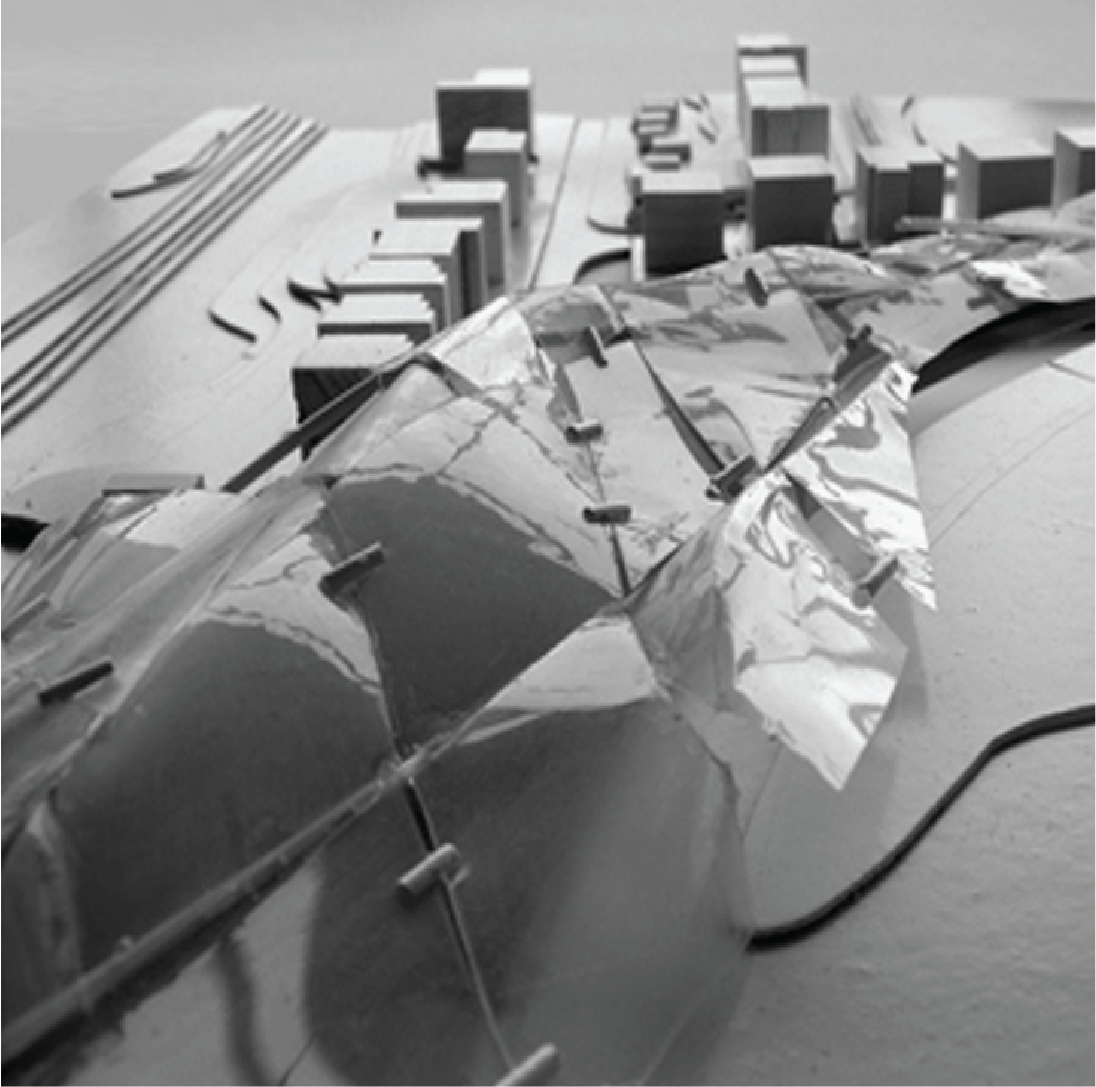

Once the general layout of the roof had been determined, it was necessary to model the form of the canopy in the context of the site to observe how the building would interact with the immediate surroundings. A massing model was fabricated at a scale of 1:100, using sprayed wooden blocks for local buildings, and layered card to create topography.

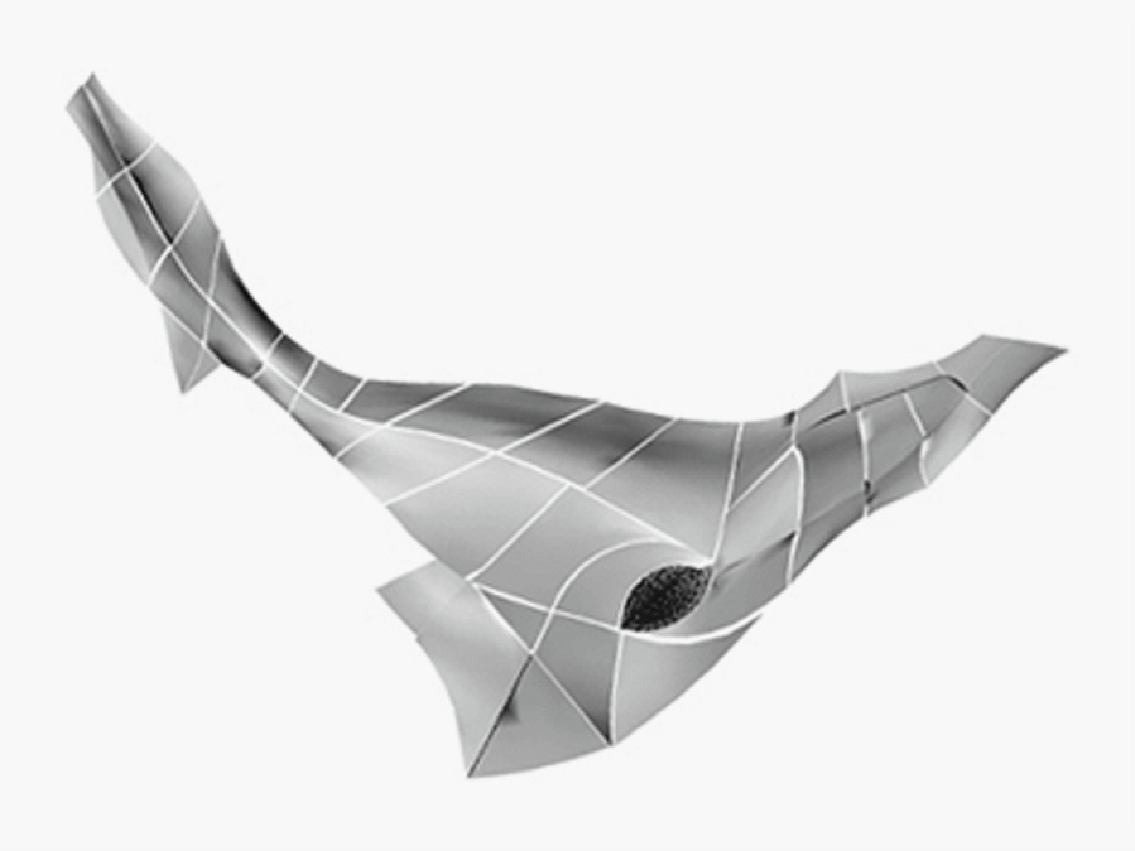

For the building, a larger scale structural model was created, employing the same method as that of the Concept Model. This structure would serve as the base for a new vacuum formed canopy.

Using a vertical vacuum forming machine, transparent sheet acetate was shrunk to wrap the new structure, creating a continuous skin to cover the entire building.

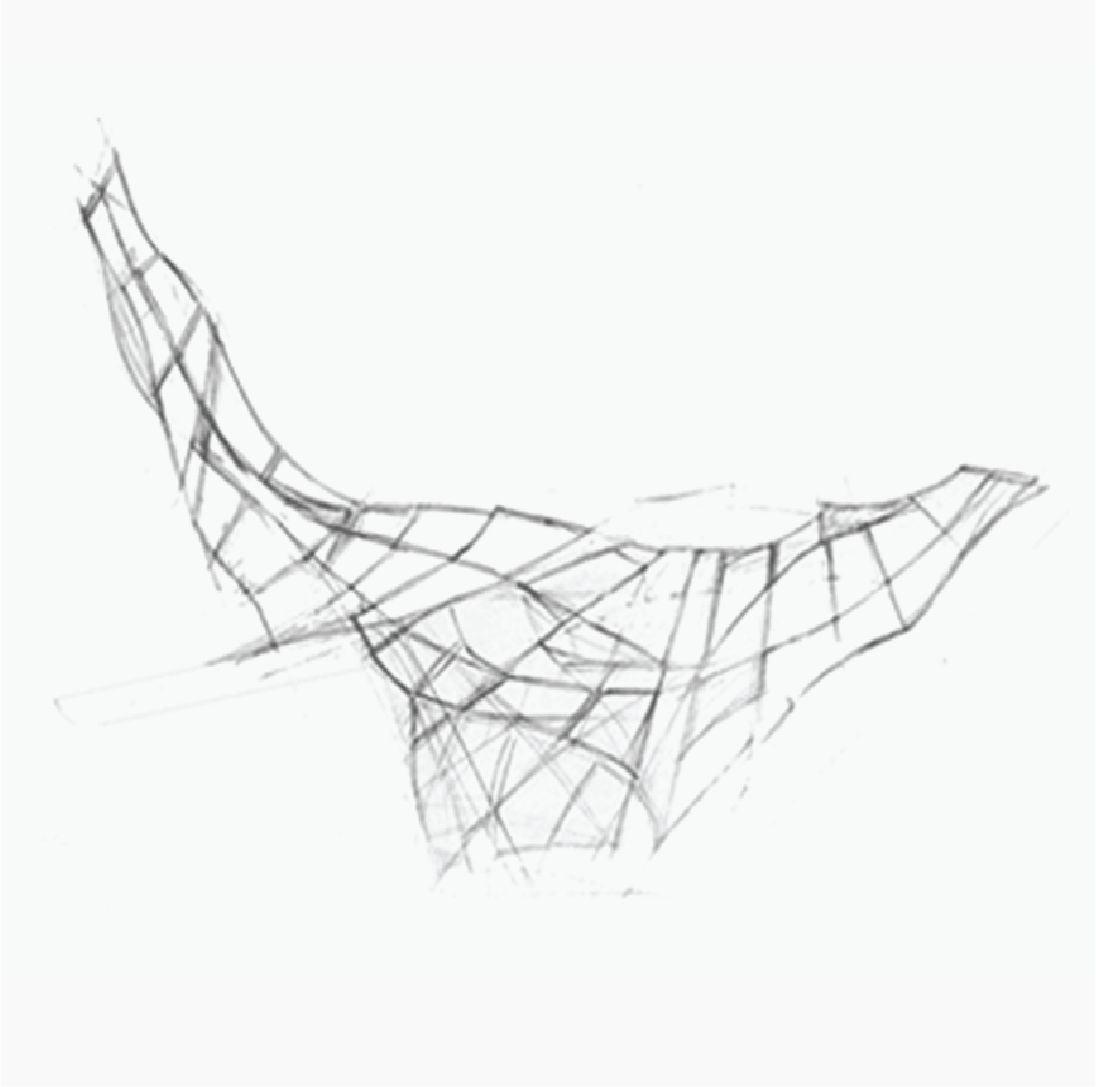

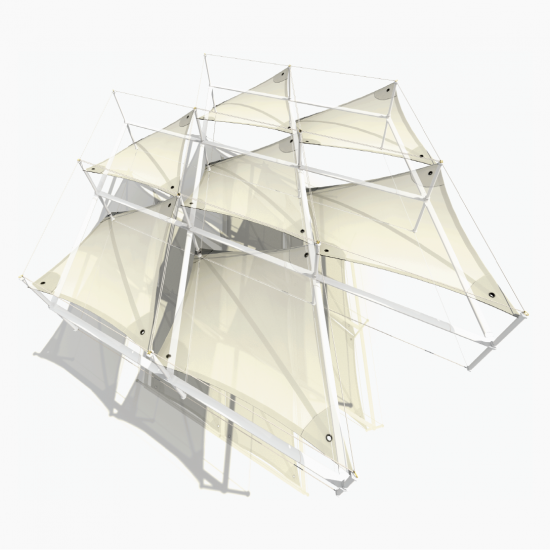

The new canopy now had to be broken down into a sea of tectonic plates of standard size for ease of fabrication. The floor layout was overlaid to determine the locations of the walls below, and the canopy was divided into a series of similar-sized façade elements.

One by one, the plates were connected to one another using clips fabricated from white plastic, to create a flexible cloth that could be draped over the structure. The final canopy model was lowered onto the site and photographed.