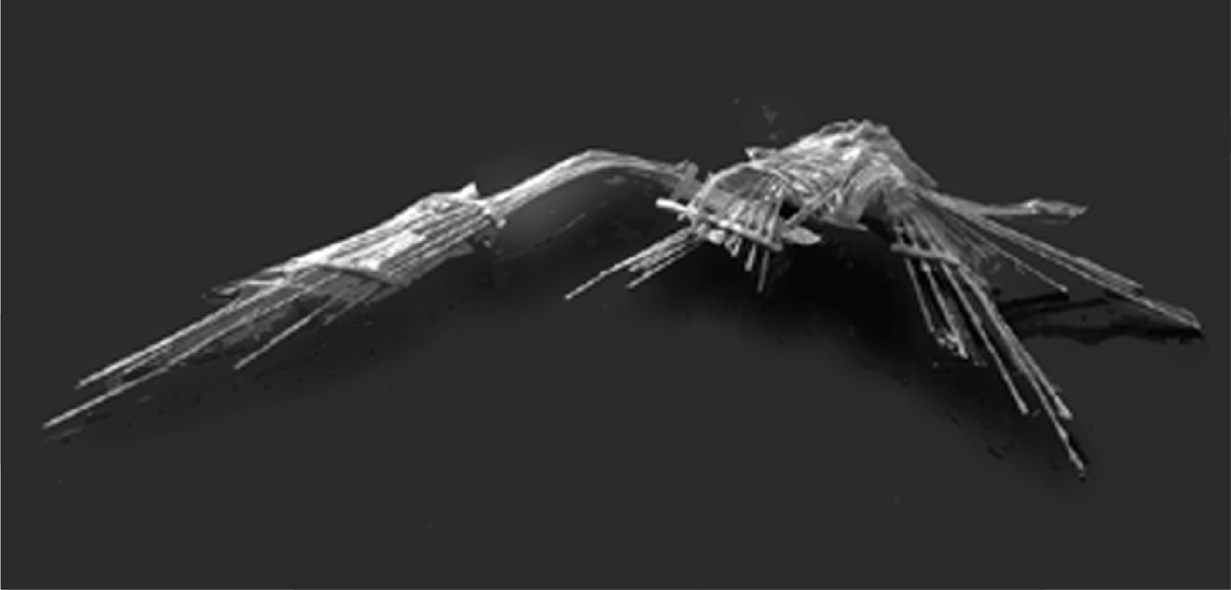

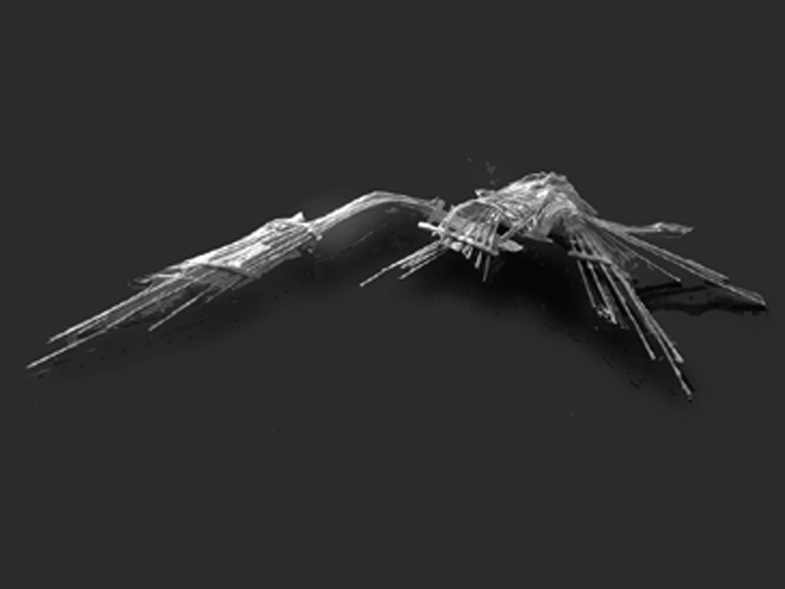

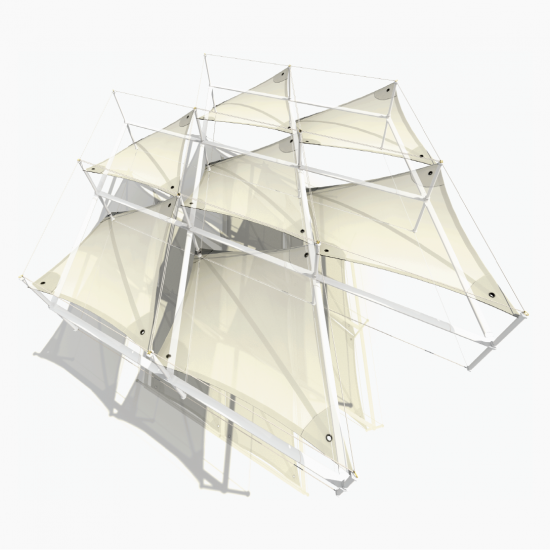

The principal materials used in the construction of the model are a white plastic coated wire, plastic square sections, and a base of card mountboard over an MDF base.

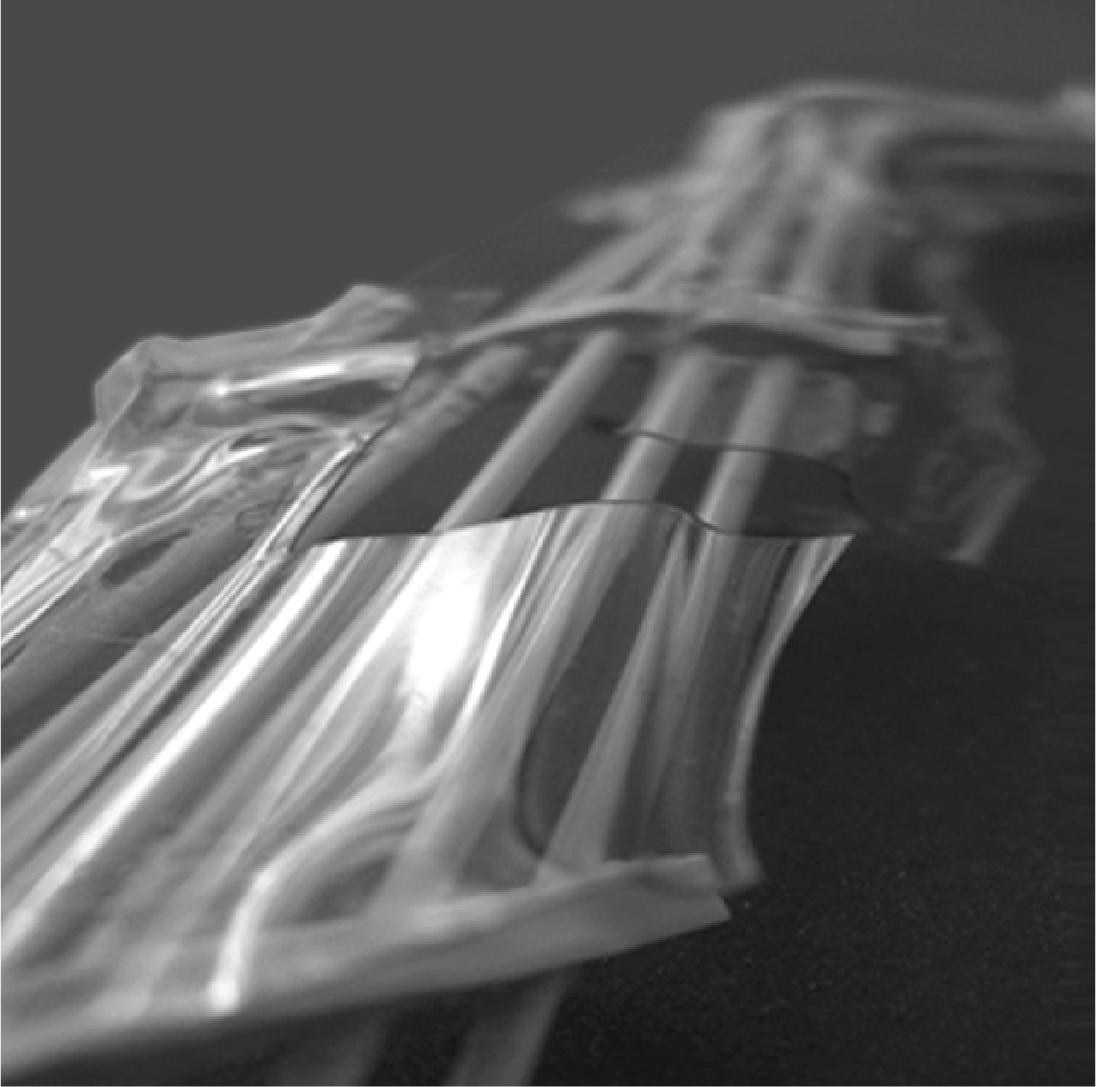

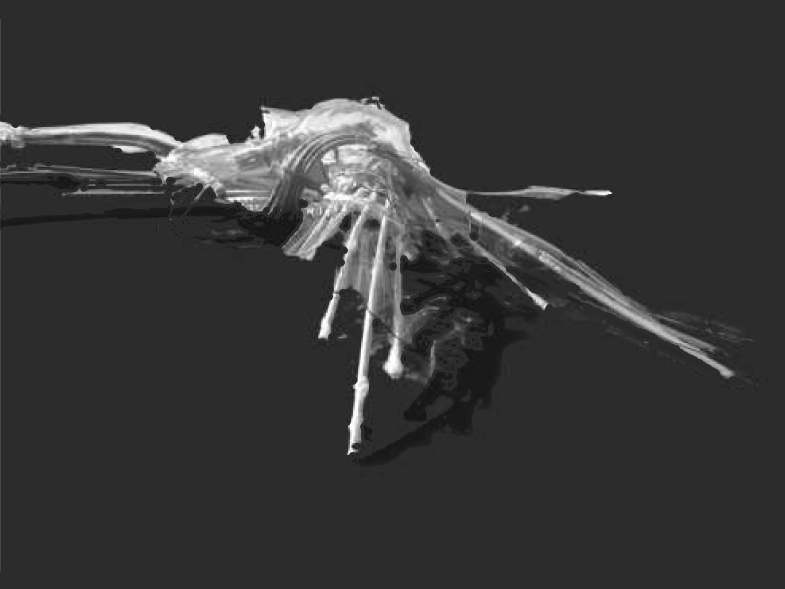

The plated structural model is constructed as an advanced step of the original Concept Model for the Water Education and Research Centre project. It comprises a structure of white plastic-coated wire, bent to the required shape and fixed, and an extruded plastic shell canopy vacuum formed to wrap the entire structure.

To read about the construction of the original structure, follow this link.

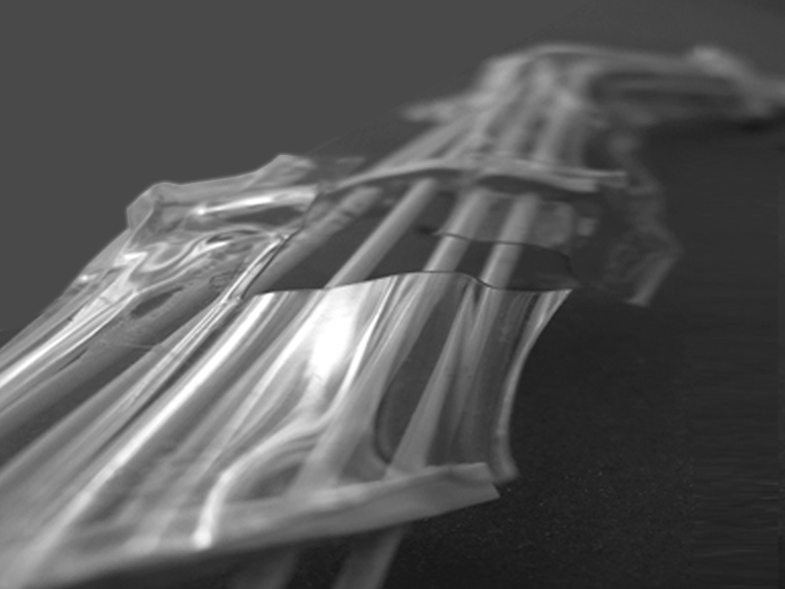

Following the construction of the base structure, preparations were made to fabricate a shell which would wrap the structure, as a gesture towards a final façade. The material used to fabricate this shell was a transparent sheet acetate, suitable for the application in vacuum forming.

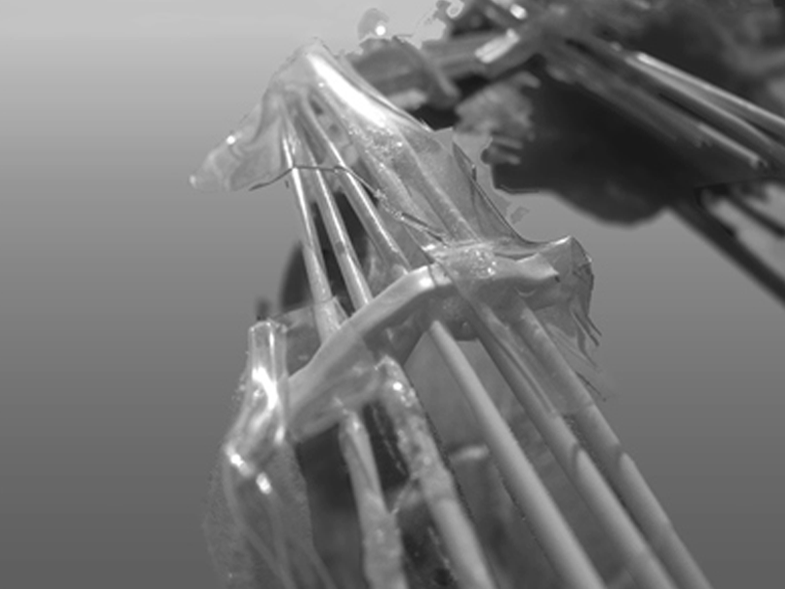

By process of vacuum forming, a softened plastic sheet is overlaid and shrunk to fit the structure. In order to prepare the model, the base has to be modified to allow the air to be extracted from beneath the model structure to ensure that the shell would snugly fit the structure.

This is achieved by drilling a number of tiny holes through the base around the footprint of the model. When the vacuum forming process was applied, air would escape through these holes and air above the softened plastic sheet forces the transparent plastic sheet to fit the structure.

The model is then placed in a vertical vacuum former, and a sheet is fixed and clamped above. Het is applied to the sheet until the plastic becomes soft and pliable. The structure is then raised until the plastic sheet is draped over the form.

Finally, air is extracted from beneath, and the plastic sheet shrinks to the structure, forming a perfect profile of the structure beneath. The resulting vacuum form can be cut and mounted to the structure to give the desired tectonic plated effect.